Apologies. That title is SO bad, but I couldn’t think of anything better, and I found myself literally staring at the screen trying to think of something. At least it’s punny and clever and multi-layered.

I talked a bit in my last update post about building a new transfer case for my Jeep. I’m happy to tell you that I’ve built and installed it, put about 300 freeway miles on it, put it through some serious 4low use, and run it up to 100mph in 2wd. I’m confident saying it’s dialed.

So, here’s some backstory… Yes, my Jeep was already four wheel drive. And yes, I have already done a transfer case upgrade. Way back in the day, my WJ had a two speed transfer case, which only allowed for a (very clever) full time pump-driven AWD mode, and a fully locked 4-low range. While, in a literal sense, this case with these modes would satisfy all conditions I’d ever encounter, it wouldn’t do it well. And it wouldn’t do it without eventually ending in tears.

The NV247 (more on the codes in a bit) was, as far as I can guess, conceived to satisfy both the wife picking the kids up from school in the rain, and the husband who needed low range when he took the family car camping once a year (sarcastic rant over now). It was a super-easy-to-use transfer case that, all things considered, performed really well. How well? I had a 247 for the first year and a half that I had my Jeep. I took it desert running, rock crawling, mud slinging, and everything in between. It performed flawlessly every time. Until it didn’t… Eventually, after 100,000 miles and more dirt than it ever expected to see, that 247 decided to retire.

That 247 currently lives here, awaiting its inevitable and glorious resurrection and delivery to an adoring soccer family who just learned the price of replacing the progressive coupler at the dealer.

I researched the 242HD, which was a direct swap for my Grand back then, and was even available on a very special few of them from the factory. This is awesome because it meant I could find the shifter from a WJ that had that T-Case, and would then have an accurate pattern on the shifter. To many (most, if I’m honest), things like that don’t seem terribly important. They know where the shifter goes for each gear, and they can operate it just fine. I don’t disagree with that at all. But to me, all those little things add up to a greater whole, and makes the driver’s seat an even more awesome place to be.

I like my shifters like I like my math problems. Complicated with a lot of letters.

The 242HD is different from the 247 in several key areas:

- 1-1/4″ wide drive chain instead of 1″ for 30% additional strength

- Two additional drive ranges available: 2wd and 4PT

- 32 spline front and rear outputs instead of 26 and 27 spline for Idon’tknowhowmuch% additional strength

- No progressive coupler (the component that transfers the torque around in the 247) that’s so prone to failure

Basically, the 242HD would be the last transfer case I’d ever need.

Before I can go any farther down the transfer case rabbit hole, I want to share what all these codes and numbers mean. There’s actually a system at work here, and it’ll help to understand what makes them all different.

New Process/New Venture Case Codes:

Each tcase has a 3 number call out, like 231, 241, 242, etc. These three numbers will tell you the basics.

First Number: The number of speeds. If it is a standard high range, neutral, low range transfer case, the number is 2. If it is a single speed with no low range, like a 133, it gets a 1.

Second Number: The size of the case, physically, and has a lot to do with how strong the case is. The case sizes currently are: 2, 3, 4, 6, 7. With 22X series being the smallest and 27X series being the largest.

Third Number: The third number tells you what type of 4wd system is in the transfer case. Current systems are designated by: 1, 2, 3, 4, 6, 7.

1 – Part time (PT) transfer case, manually shifted. When in 4wd, front and rear driveshafts are locked together. If its a 2 speed tcase, then it would have 4 positions, 2wd, 4wd, N, 4 low part-time (LPT). These cases are shifted by a lever on the floor. Example: 231, 241, 261, 271

2 – Part time transfer case plus Full time (FT),manually shifted. A geared differential is used to allow the driveshafts to turn at different speeds, while still applying torque. Some are 4 position and some are 5. 4 position have 4FT,4PT, N, 4LPT. 5 position boxes get a true 2wd where the differential is bypassed and all the torque goes to the rear driveshaft. These cases are shifted by a lever on the floor. Example: 242, 242HD, 242AMG

3 – Part time (PT) transfer case, electrically shifted. Everything is the same as a -1-, except an electric motor is used to shift the transfer case. Instead of a lever on the floor, you have a button or a dial on the dash. Example: 133, 233, 243, 263, 273

4 – Part time transfer case plus Full time (FT), electrically shifted. Everything is the same as a -2-, except an electric motor is used to shift the transfer case. Instead of a lever on the floor, you have a button or a dial on the dash. Example – 244

5 – This is found on 2005+ Jeep Grand Cherokees with the Hemi.

6 – Active on demand System. Front and rear axles are constantly monitored electronically to detect any differences in speed due to wheel slippage. When a speed difference is detected, a computer signals the transfer case clutch pack to engage. Torque transfer is transparent to the driver, meaning the driver can tell it happened, like all four wheels are now pulling, but you didn’t have to pull a lever or turn a dial to activate it. Example: 226, 236, 246

7 – Progressive on demand system. The vehicle operates in 2WD. When traction is lost by one of the driving wheels, power is automatically transferred to the other axle. Torque transfer is transparent to the driver, meaning the driver can tell it happened, like all four wheels are now pulling, but you didn’t have to pull a lever or turn a dial to activate it. Example: 247

via 96superflow at s10forum.com

So, to deconstruct my transfer case code, a 242 is a two speed (4-hi/4-low) (first number), medium duty (second number) case, with manually shifted part time and full time gear ranges (third number). To make things confusing, New Process and New Venture are actually the same company. But they do have an interesting history:

New Venture Gear, now a division of Magna Powertrain, is an automobile and Light Truck transmission company that was started in 1990 as the first ever joint venture between any of the Big Three US automakers. General Motors and Chrysler Corporation were the participants. Operation and management of Chrysler’s New Process Gear Syracuse, New York plant and GM’s underutilized Muncie, Indiana Hydramatic transmission plant were shifted to New Venture Gear Company.

From Wikipedia

To make things even more confusing, Chrysler/Dodge/Jeep decided to add their own suffix codes to the cases which seem to follow no rhyme or reason whatsoever. The Jeep 242HD and the Dodge 242DHD and the Dodge 242D are all identical cases, but should not be confused with the 242J which is a pared down, weaker version of the 242HD. yay.

So I ordered a 242HD from a junk yard online. What arrived two weeks later was a 242J. Livid, I called the junk yard to complain, at which point they invited me to send the case back on my own dime for them to determine whether I was lying to them or not, and IF not, they would initiate a refund for “store credit” and I could look for another one. In brief, that was not an acceptable option. Too many variables (also, fuck those guys). Instead, I bit the bullet and installed the 242J in my dub. Effectively, the 242J is just the same as a 247, but with 2wd and 4part-time instead of the progressive coupler. Same chain, gears, and strength though.

meh. I’m over it.

Fast forward to a couple months ago, when the 242J started to slip and jump teeth. I decided that instead of dumping money into this case I never wanted in the first place, I’d go ahead and build the last case I’d ever need. Again.

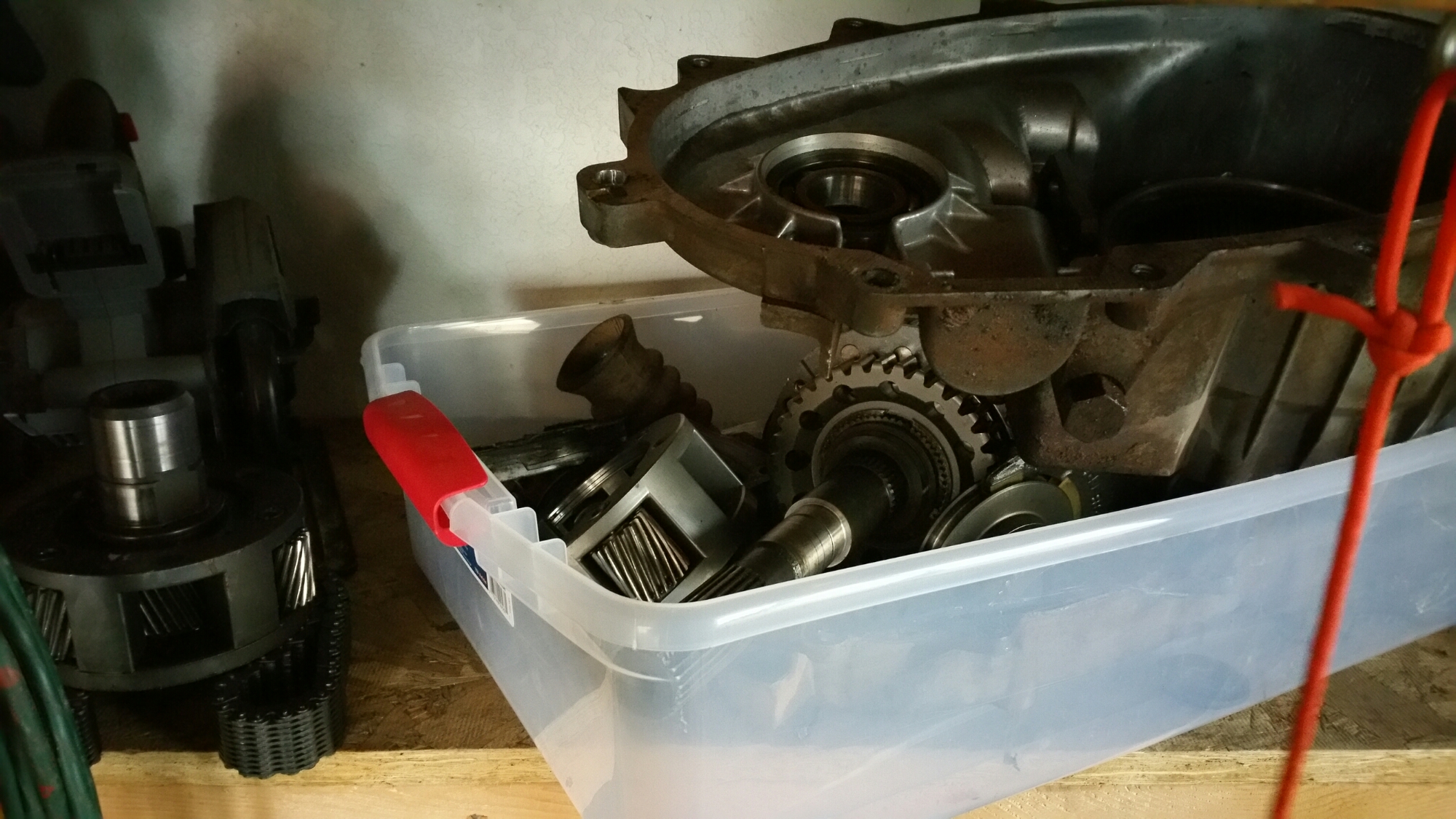

That 242J currently lives here. In shame.

One thing for sure, I wasn’t about to get stung like before. So I did a year and a half’s worth of research before I bought the next transfer case. The result? I got a perfect case here in town with perfect internals for less than half the price, and I even added components to make it even stronger.

BEHOLD! THE 242XHD! (I know, right?)

This is how it sat before I tore it down and cleaned it up. Notice that long-ass cone sticking out at us? That gets replaced by a new bright red machined aluminum cap and seal provided in the IRO SYE kit, as you’ll see below.

In these two photos of disassembly, you can see how power is transferred from the input (at the bottom) through all the gear assemblies. Those gear assemblies move back and forth (up and down?) to change alignment with each other when the shift select forks (connected to the rod in the middle) are actuated by the shift mechanism inside. A chain connects the mainshaft to the front output (on the left), and then continues out to the back, and violin! That’s how transfer cases work.

The keen observer will notice in these photos that the mainshaft has already been cut and tapped. They are in fact reassembly photos! I’m so sneaky! For the purpose of explanation though, it’s irrelevant.

Here it’s the almost completed case, with the chain installed, oil pump in place, and the RTV setting up.

Installing the IRO cap and seal

Here’s a fancy picture of the complete case that I took with my new Samsung Note 4! (Sponsor me Samsung)

Build

I totally expected to post a link here to some awesome transfer case write-up that I would easily find on Jeepforum.com or similar but, much to my surprise, I could find no such thing. Methinks I shall remedy this one day soon. I have the actual service instructions from a third party (like Alldata, but not Alldata) that I will reword enough to avoid copyright infringement, and then share with you all here. There are several intricacies that I found along the way, that would prove really useful to anyone looking into this swap. As seen above, I have a 247 and a 242J that need rebuilding, and I could make a fairly comprehensive WJ transfer case guide with them.

Until then, please enjoy the few pictures I DID take during the process.

Upgrades

I broke this project into three major components:

- Rebuild

- Upgrade planetary gearset

- Add Slip Yoke Eliminator kit

Rebuild:

I bought a complete rebuild kit, which includes all the bearings, seals, and o-rings. I bought a brand new OEM spec chain (I couldn’t find any uber-chains to upgrade with) to replace the old one with unknown miles. There are actually two different rebuild kits for the 242, because there was a change to the input shaft dimensions around 94-95 that threw everything into a tailspin. I’ll detail this when I post the full build, but for now, be aware that you could have either a 16 or 24mm input shaft bearing, and the two aren’t compatible (the case housing is the same, but the input shaft won’t fit, and will fall 8mm short of seating fully).

Planetary Gearset:

The planetary gearset is what takes all the force from your transmission output, and distributes it to the main shaft inside the T-Case for distribution out to the driveshafts. Without going too much into detail, the planetary is a cage with one central “sun” gear and some number of “planet” gears that revolve around the sun gear (see pic below). Typically, most 24x and lower series cases come with three planet gears. However, there was a Dodge 241HD in a very short run that offered six planet gears instead of three, so I knew it was possible.

Here is the old 3 pinion gearset (right) and the 6 pinion set (left) with the WJ input gear installed.

PROTIP: I’ve seen the unfortunate result of one of the dowel pins dropping out of the gearset. The transfer case was instantly and totally destroyed. I put two quick tack welds on the “bottom” of each pin to virtually guarantee that this could never happen on this one [crosses fingers]. So far, I haven’t noticed any vibrations (nor did I expect them) or any other negative outcome from this. If I do, I’ll crawl back here and admit it.

All of that nonsense above means that, while the 242 lists an input torque capacity of somewhere around 1900lbs, the 241 with the six pinion gearset was rated to a ridiculous 5555lbs of torque, more than I and my WJ could ever exert on it. Bombproofing.

I found two points worth sharing on this topic:

- I could not find a difference in dimensions between the planetary carrier for a 24x series and a 23x series case. I believe they are identical, but didn’t find anything definitive either way. I believe it enough that I put one in my rig, and have had no problems so far.

- While I believe the planetary is swappable between 23x and 24x (and possibly other) cases, the planet gears came with two different kinds of edge on them, and mixing the two would be catastrophic. Jeep and some Dodge cases have angle-cut or beveled edge gears, while some Dodge cases have straight edges on the planet gears. Make sure to confirm this before ordering.

So, will any of that transfer (lol) to an actual usable upgrade to the transfer case or my Jeep’s overall performance? I don’t know. I do know that I’ll never have to worry about breaking it, and that’s one less thing to be stressing on the trail.

SYE:

This topic has been beat to death online, and if you’ve made it this far, you probably already know what an SYE is. However, for you Mom, an SYE is a slip yoke eliminator. Because of the nature of moving suspension and the universe itself, the driveshaft needs to compress and extend while the suspension cycles up and down. Normally, this is done at the connection between the transfer case and the rear driveshaft without issue, but as suspension gets taller, that becomes less than ideal, because the range of travel increases. An SYE replaces the slip joint at the output of the transfer case with a fixed yoke. The solid driveshaft is then replaced by one with a slip joint in the middle, allowing for more extension/compression and a stronger connection between the case and the driveshaft. This is the factory arrangement at the front output of the case, so no modifications were necessary (Is a front slip yoke even a thing? I’ve never heard of one).

There are generally two accepted types of slip yoke elimination. The first and most recommended, a true SYE, is when the mainshaft is actually replaced with a shaft designed for a fixed yoke from the beginning. I’ve never met a true SYE (EDIT from the distant future: This seems to be a silly statement in retrospect… Of course I haven’t seen a “true” SYE, because it’s called a fixed yoke.) in person because I’m not fancy. These aren’t typically available for most transfer cases out there, including mine, so we resort to the hack and tap method. Hack and tap because see below.

The thing that makes an SYE so daunting a project is that, in most cases, you’re cutting the end of the main shaft off perfectly flat, and then drilling a perfect hole perfectly in the center of the shaft to a perfect depth blah, blah, blah… I skipped that nonsense and tore the mainshaft down completely, got the exact dimensions I needed, and then took it to a local machine shop to have the work done. I’m not ashamed to say it’s perfect. I’m very proud of the work I did, taking some measurements and then handing it off to someone else to do the work. It came out great!

In my case, since both front and rear are 32 spline, the two front and rear yokes are practically (maybe literally) identical. Here’s what’s really awesome: The front and rear shafts are interchangeable now. I can carry one spare that will work at either end of the Dub. Nice, right?

The long rear output cone I mentioned earlier is replaced by this snazzy red joint from IRO.

And at long last, here is the transfer case completely cleaned up, rebuilt, and installed.

Parts & Sources

242D Transfer Case: Sourced from a 2000 Durango in my local junk yard

Crown OEM replacement chain: Part# 5003453AA Purchased on Amazon

242D master rebuild kit: Purchased from Transparts Warehouse

Machine work: K&M Machine – Flagstaff AZ

Driveshafts: Vanguard Truck Center – Bellemont AZ

SYE: Iron Rock Offroad 242 SYE kit. Looks like they have a new site now too…

Planetary: Duke Powertrain parts Plus. This guy is an eBay seller, but I had a great experience working with him. A++ Would shop again!!!!!!!!!!

Nicely done!

I am looking for a 242d from a durango and was wondering if the mounts are all the same for a 5.2 and the 4.7 trans?

what did you do about the linkage from the shifter to to tcase?

Thanks!

I would wager that you could put a T case from off a 5.2 on your 4.7, being that all jeeps use the same pattern for their T-Cases, but I would make sure to do heavy research on that. You’ll want to find out what transmission that 5.2 is attached to, and cross reference that bolt pattern to that of a 4.7, making sure they match exactly. It’s a virtual guarantee however, that the input shaft won’t match. So you’ll have to swap the one from your current (247 I’m assuming?) into the new case.

As far as the linkage, it’s all the same until you get to the actual shift arm on the T-Case. The shift arm has to be modified to work (shortened and straightened, I think).

Nice work on the case. What did the machine work on the mainshaft run you?

Thanks! I believe it was $35 or $40. Not even a full hour of labor.

I cannot decide if I want to hold out for the Novak or not.

If you’re comfortable with taking all the measurements yourself, any machine shop can do the cut and tap.

Does IRO not provide that instruction with the kit?

I honestly don’t remember. It might. The instructions are probably available on their site.

The case look good, what did the machine work run?

DO you still plan on doing the detailed re build….after reading this thread i already purchased ther planet gear from your e bay guy….the day after i e mailed him he had listed the part and i snatched it up immediately…my lucky day! So i plan on doing this build to a t on my wj…so any tips or a re build thread like you mentioned you may do in the future would be crazy helpful since i have never changed a planet gear set..let a lone re built a case. Im pretty good at re building stuff so i dont see too much of a problem…just knowing what you know after the build any tips or critical steps that you feel need to be noted for my build would be amazingly helpful. Thank you for the inspiration for my transfer case build and i look forward to hearing back from you!

Al

I tell ya, I would love to, but I don’t forsee the opportunity in the near future. I’ve got a buddy who will be upgrading his case at some point, but I don’t really know when. I think you can find factory service manuals online for the 242/231/241 etc for free. That’s probably as detailed as you’d need if you’re comfortable turning wrenches. The input shaft you have now is gold. Be sure it gets installed in the new case. The planetaries have two different gear cuts (I think I mentioned this in the post). Be sure to get the correct ones. Disassembling the planetary gearset is a matter of removing two snap rings. Very simple.

Building the case is straightforward. Take LOTS of reference pictures as you disassemble.

Thanks for reading!

Ah ok cool….you mean the input shaft on the 242 d will be gold conce the planet gearset is installed in the case? Also…the planet gear set u actually got from Duke …i specifically told him i wanted to do your exact build so he sold me one that he said would work for my application….so the teeth cuts should work right? If there not tue correct cut how can i fix the problem…new planet gear…or can the 6 gears be changed?

when you ordered the 242j did it have the extended tail cone like the 242d?